The Versatile Applications of Finger Joint Wood: Where Precision Meets Function

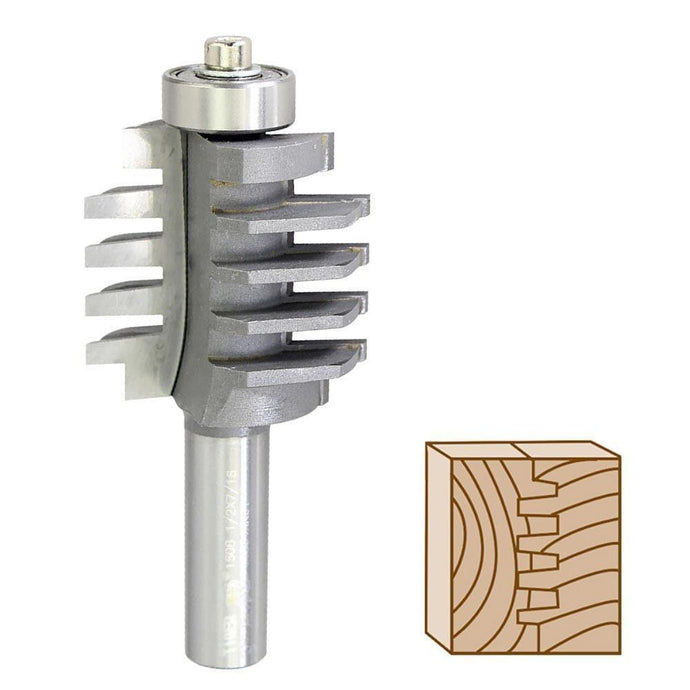

Finger joint wood, characterized by its interlocking rectangular notches, serves a range of practical and aesthetic functions in woodworking. This traditional joinery technique is valued for its strength, precision, and adaptability, making it a popular choice for various applications in both residential and commercial settings. Understanding the diverse uses of finger joint wood can illuminate why it remains a staple in modern woodworking practices.

One of the most common uses of finger joint wood is in the construction of cabinetry and furniture. The strength of the finger joint, achieved through its precise interlocking design, makes it an ideal choice for building durable and stable components. Cabinets, drawers, and furniture pieces benefit from the enhanced structural integrity provided by finger joint wood. In particular, it is often employed in the creation of drawer boxes and cabinet faces, where durability and load-bearing capacity are critical. The consistent, tight-fitting joints ensure that these elements withstand daily use and retain their functionality over time.

Finger joint wood is also widely utilized in the production of moldings and trim. The ability to join longer pieces of wood seamlessly makes it suitable for creating long, continuous sections of trim or molding without the need for extensive splicing. This application is particularly useful in projects requiring long runs of material, such as baseboards, crown moldings, and door casings. By using finger joint wood, craftsmen can avoid the visible seams and potential weaknesses associated with traditional splicing methods, resulting in a cleaner, more professional finish.

In addition to cabinetry and trim work, finger joint wood finds its place in the realm of prefinished wood products. This includes applications like prefinished panels and engineered wood products, where finger jointing is used to create long, uniform boards from shorter pieces. The technique allows manufacturers to produce large panels or boards from smaller segments, which can then be finished with various stains or coatings before assembly. This approach not only maximizes the use of available wood but also provides a high-quality finished product with minimal waste.

Another notable application of finger joint wood is in the construction of architectural millwork and custom woodwork. This category includes custom-built features such as bookcases, display cabinets, and specialized furniture pieces. The precise nature of finger joints allows for intricate designs and custom configurations that would be difficult to achieve with other joinery methods. Whether creating a bespoke library with custom shelving or designing a unique piece of furniture, finger joint wood provides the necessary strength and flexibility to realize complex and personalized projects.

The durability of finger joint wood also makes it a suitable choice for structural applications. In certain cases, it is used to reinforce structural components or as a base material for more robust construction elements. For example, finger jointed lumber can be employed in framing applications or as part of composite materials, where the joints contribute to the overall strength and stability of the structure. This application is particularly valuable in scenarios where long, straight pieces of wood are needed without the natural defects that can compromise strength.

Furthermore, finger joint wood is utilized in creating various types of wooden containers and packaging. Boxes, crates, and shipping containers often use finger jointing to enhance their structural integrity and longevity. The technique ensures that these containers can handle the stresses of shipping and storage while maintaining their shape and functionality. For applications that demand both strength and aesthetic appeal, such as decorative boxes or gift containers, finger joint wood offers a solution that combines practical performance with an attractive appearance.

In the realm of DIY and hobbyist projects, finger joint wood provides a valuable option for crafting and home improvement tasks. Woodworkers and enthusiasts use finger jointing to create a wide range of projects, from small furniture pieces to intricate decorative items. The ease of use and ability to achieve precise, strong joints make it an appealing choice for those looking to produce high-quality results in their home workshops. Additionally, the technique allows for efficient use of materials, reducing waste and making it a cost-effective option for various projects.

Overall, the versatility of finger joint wood underscores its value across a range of applications. From cabinetry and furniture construction to architectural millwork and packaging, its strength, precision, and adaptability make it an essential tool in the woodworking arsenal. By leveraging the unique properties of finger joint wood, craftsmen and manufacturers can achieve durable, high-quality results that meet both functional and aesthetic needs. Whether in professional settings or DIY projects, finger joint wood continues to demonstrate its relevance and importance in the world of woodworking.